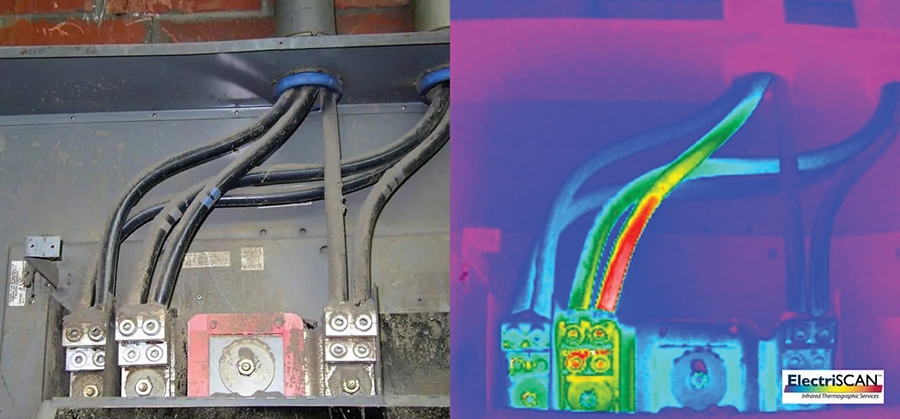

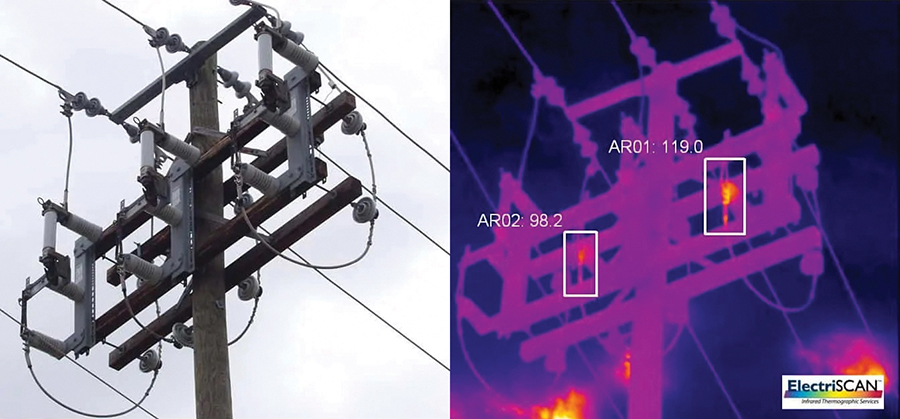

Infrared thermography is a widely used technique for electrical switchgear testing, and is routinely employed by thermographers across the country. The use of infrared for the routine inspection of electrical equipment has been well-established as a critical element of preventative/predictive maintenance (P/PM) programs for facility managers.

By regularly inspecting electrical switchgear using infrared thermography, potential problems can be identified and addressed before they result in disruptions or damage, helping to minimize the risk of costly downtime. Our state-of-the-art technology and expertise allow us to provide reliable and accurate results for our clients, helping to ensure the smooth operation of their electrical systems.