Infrared Inspections of Electrical Equipment

We make asset management easier through infrared technology

Advantages of Infrared Electrical Inspections

Some of the many benefits of our infrared inspections:

We Make Electrical Asset Management Easier

Your trusted partner in safeguarding your electrical systems

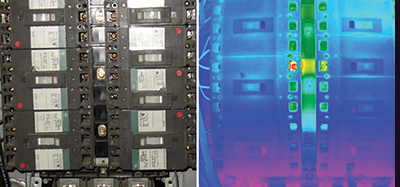

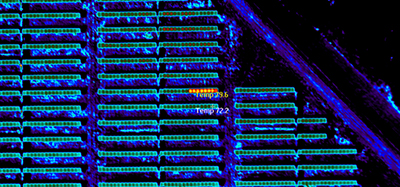

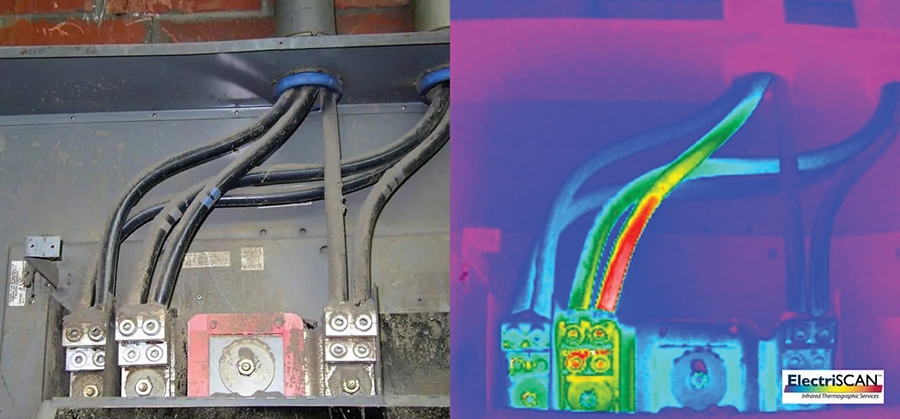

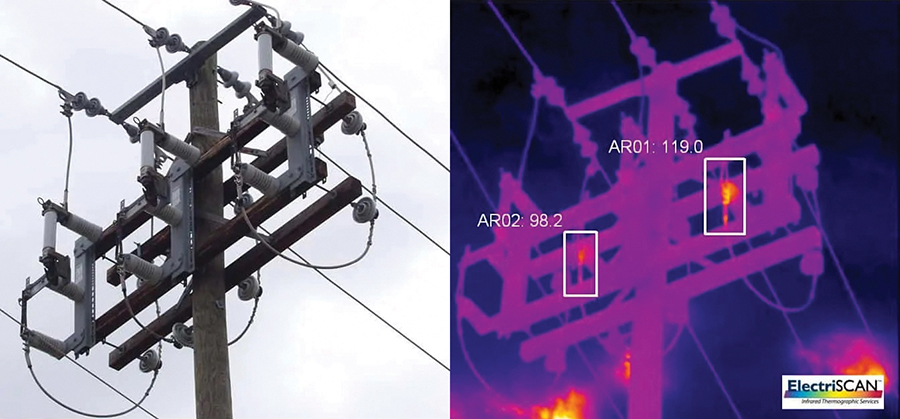

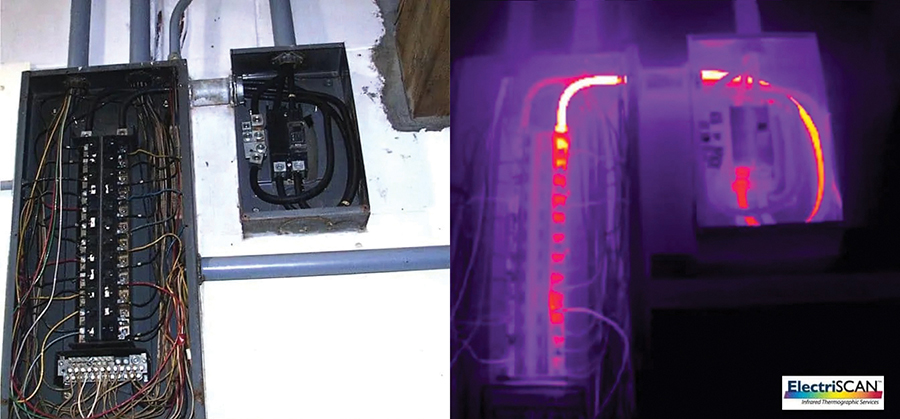

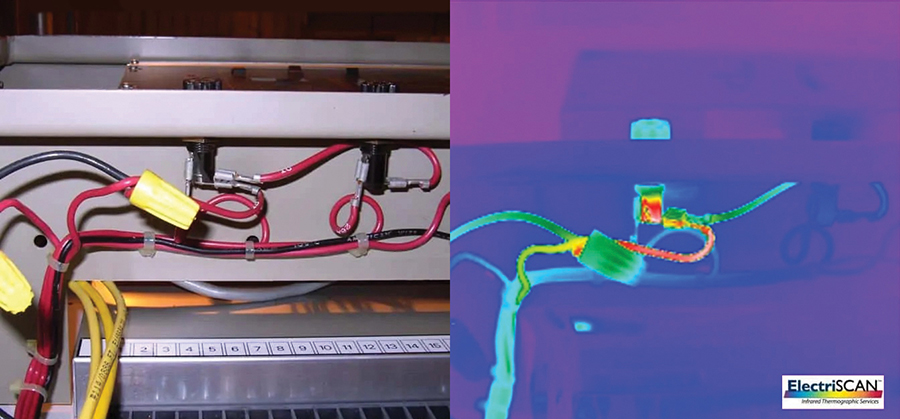

ElectriScan™, a specialized unit of Stockton Infrared Thermographic Services, Inc., is a leading provider of advanced infrared electrical inspections. Our services are designed to support maintenance testing for Electrical Switchgear, Data Centers, and Solar Panel Installations.

Our infrared testing solutions have been embraced as a critical component of preventative/predictive maintenance (P/PM) programs by facility managers across various industries. Our state-of-the-art technology allows us to identify potential problems with electrical equipment before they cause disruptions or damage, enabling proactive maintenance and mitigating the risk of costly downtime.

Meet the Team

Greg Stockton

Alejandro Tache

Mike Clark

GET IN TOUCH

Thank you for your interest in ElectriScan! If you have any questions or would like to schedule a phone call or meeting, please don’t hesitate to call, email, or complete our contact form.